Silent Partner modifications

Thursday, July 13, 2006

Sorry, no pics today.

I'm living on the Hans Christian...in southern Louisiania...on the hook (at anchor). This means no utilities, particularly shorepower. I use an inverter to run my laptop and occasional other small items when absolutely necessary (power tools, shop vac, very rarely microwave). The only air conditioning on board, or actually that used to be onboard, was an old and not particularly effecient unit. Most all AC units run on 110vac. This is primarily because they draw a lot of power. Except for electric water heaters (or those unlucky souls who tote around minuature electric washer/driers for their clothing) AC consumes far more power than any other appliance. The one exception is the "DC Breeze" unit built by Glacier Air. They also build excellent refridgeration/freezer units. I currently have little money, and so do not have the 12v DC Breeze. When I'm working at the boatyard in the heat during the day, and eating and sleeping without AC, it's not all that bad. You sweat sometimes, but adjust mostly except for those couple nights a month that are especially warm. I have a few 12v fans that help significantly, though they are a little noisy and consume some power. Eventually I want to replace them with the Hella two speed units which are extremely power friendly and quiet. During the school year when I'm stuck in air conditioned classrooms all day, and commute with the ac on in the truck, sleeping without ac becomes less comfortable. Even a little to drop the temperature down to 80 or even 85 and pull 10 or 20% of the humidity out would be great. Eventually I want to add a DC Breeze unit. I'll set it up so it is possible to cool the salon down a little, but it's primary task will be cooling the pullman berth only. The smaller space the less power it takes to keep it cool. And rather than running the engine an hour or two every single evening I really want to add some solar panels. Actually I'd like to build a fiberglass hard top instead of a canvas bimini, and mount the solar modules on top. This would not only cover my usage for lighting, laptop, fans, propane solenoid, and stereo, but actually let me run the refridgeration modestly (having a well insulated icebox and a new 12v fridge unit that was installed just before I aquired the boat helps save power also), and even run the AC sparingly without ever having to run the engine to charge batteries during the summer. In winter the panels won't put out as many amphours in a day, but cooler temps mean less power needed for food coolings, and no need to run the AC. With the currently decent effeciency of12.5% solar panel modules I should be able to get 300 amphours daily in the summer without trouble. Part of this is also because new solar charge controllers are very advanced. Several units now use a form of DC-DC converter. Instead of requiring an array voltage exactly matching that needed to charge the batteries, and resisting and wasting the rest, they take in whatever voltage and amperage, or maximum wattage, the panels put out. This can be anything from 12v to 48v typically. They then convert the voltage to that which is desired to charge the batteries, so the wattage is maintained and maximum possible amperage delievered to the batteries. This is also convenient because the solar modules used don't have to match the battery bank voltage. Sometimes it is cheaper to get 24v nominal panels now because they are often stacked for larger house and landbased systems. The wattage can also be the same but higher voltages with lower amperages mean smaller wires are needed (cost and weight savings). I personally like the Outback brand of equipment. They offer true sinewave inverters/chargers (best for electronics and laptops) and effecient solar charge controllers. They are interfaceable and programmable which is a nice feature. They also feature battery temperature sensing to protect the $500 of batteries the entire boat's system relies on. The central controller unit also monitors charge amperage and total amphours so it's easy to monitor if I'm drawing off more than the panels are replentishing.

Wind generators are also a great invention. I happen to have an old WindBugger which works just fine...when there's wind. Problem is most the time there isn't enough wind around the Tchefuncte river to spin it at all, let alone fast enough to generate useable power. In the worst part of the summer there typically isn't even the slightest breeze (except for hurricanes, which aren't the best time to leave a wind gen out there to shed alumimum blades through the deck). They're nice, but just not practical for sitting on anchor most the time in Southern Louisiania. There also ins't much if any current so I can't use a water generator. This area is basically a windless, currentless tideless, elevationless, humid, sunfilled hole...perfect for solar.

I could also use a diesel generator I suppose. On a larger boat or poweryacht that is certainly be a viable and popular option. I really lack the space for a diesel generator, even a compact 3kW unit. Actually I can buy the solar panels and charge controller to keep up with my usage for cheaper than a generator. And then a generator requires maintenance, parts, and fuel $ to run. It also generates noise besides electricity. Now I could use the heat output to heat potable water, but I can add solar water heating pipes and do the same during the summer without buying any diesel. And it's silent.

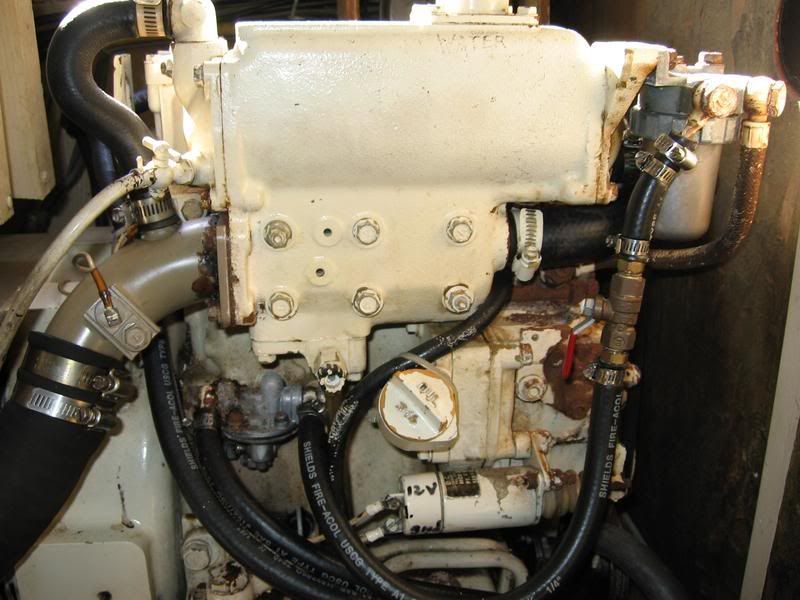

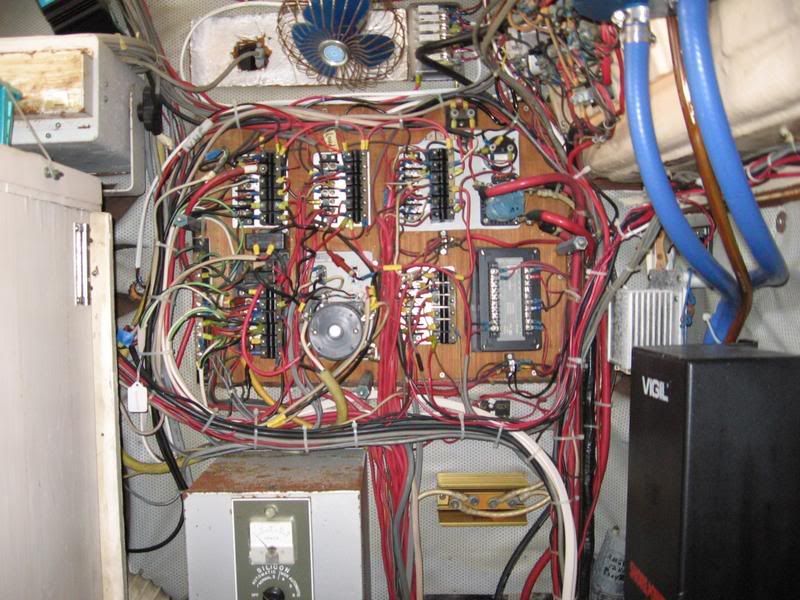

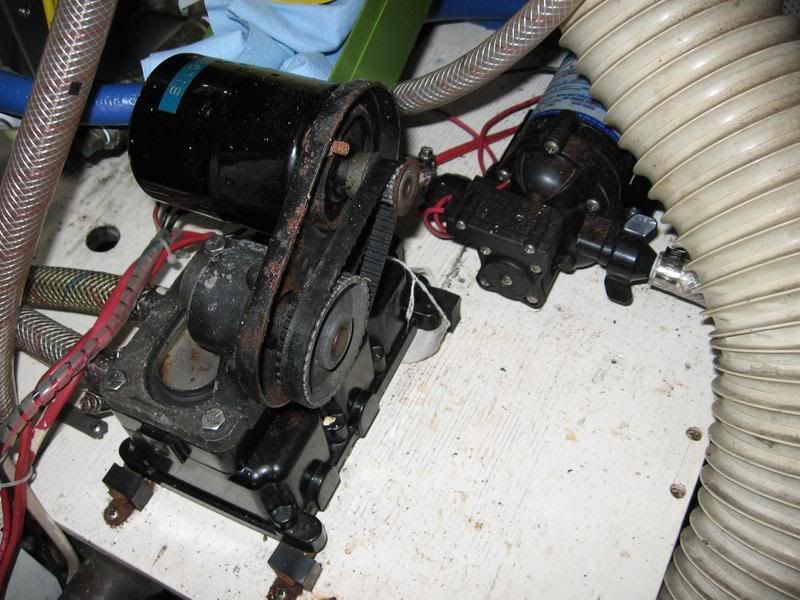

Before any of this I have some general wiring to clean up onboard. I'm also swapping my main battery bank and hot water tank. Currently the batteries are in the engine room (where it's hot and full of viberations) and the hot water tank is under the dinette seating where I'd rather it be cooler and where viberations are limited. The swap will put the tank near the engine, shortening the hose runs between engine and tank for the water heating exchanger. The main batteries will be more centrally located in the boat. This puts them closest to the main distribution panel as possible which lowers losses in wiring and reduces the cost of the new wires. It also moves them closer to the windlass and future locations of the AC unit and Electrasan sewage treatment processor. This again reduces power losses in wiring and less wire is cheaper than more wire. With the batteries under the dinette I'll be more likely to check their electrolyte levels more frequently and add distilled water than when they were wedged in the far corner of the engine room under the cockpit. This whole change also means relocating the pressurized fresh water pump. Not difficult since I'll slowly replace all the vintage 1980 copper plumbing with pexpipe anyway and routing wiring isn't a big deal. Only thing is I'll be without water or power initially. Then I'll still be without water for probably a day or two. No big deal really, so long as I get it done before I lose access to the shower at work in november and begin showering onboard full time.

Speaking of showering, the shower is in the forepeak and the hot water tank will be in the aft end. Running the shower waiting for the hot water to arrive can waste gallons. At some point I'd like to install a recirculation line an valve and a fast acting temperature gage. That way the cold water can be returned to the fresh water tanks. A temperature valve would make it easy to know when to shut the valve and get in the shower without wasting any of that preciously heated water.

Now in the winter there's less light and the sun isn't as intense, so I wont' get as many amphours from the solar array. But then I also won't be using the AC. I'll burn the lights more. However, I'm finding inexpensive sources for Luxeon LED's to relight the entire cabin. Using them I'll hardly consume any amps lighting the cabin. It actually does get cold here in the winter. Temperatures near, even just below, freezing at night for months and not all that warm during the day even though the sun is around. Staying away from shore power and diesel generators I'd still like to not freeze all winter. Last year I did okay heating the smaller boat with oil lamps and layering on cloths. I also typically studied at teh lab at school and pretty much used the boat for eating and sleeping. This winter I'd really like to keep the cabin more inviting with a diesel heater. The Hans used to have one, actually it was removed just before I got ahold of her. The closed off hole for the stovepipe and charlie noble hadn't even been fully faired in yet. If I can afford one it's the most economical and carefree way to me to heat. I could use propane, but it's explosively dangerous and I hate filling up propane bottles. I'd rather draw a daily quart or two of fuel off the 140 gallons in the main diesel tanks and fill up at the dock every year or two instead. I should also be able to add a few coils of copper tubing around the stovepipe and circ antifreeze through them and the hot water tank heat exchanger to have heated water for dishes and showering in the winter.

Being in Louisiania it's slightly humid. Actually any boat is a humidity and moisture trap. Many people use dehumidifiers and air driers, but they like 110Vac. I don't like 110Vac and the high power consumption of such inventions while on anchor. AC and a diesel heater will help remove moisture throughout the year. Still, some sources of moisture seem doomed to exist in the boat. I use a propane bbq much of the time for cooking. The rest ot the time Silent Partner has a wonderful 4 burner propane stove with oven in the galley. Propane is nice to cook on, but part of the combustion process creates water vapor. Rather than intensifying the sauna effect in the cabin I want to add a stove hood with fans. I plan to use computer cooling fans (12v and very effecient and quiet) installed in the hood I'll have to build. I'll vent out the deck, with 4" deck plates I can block off just like the dorades for the foulest of weather situations.

At the same time I want to build a teak box to house the propane tank(s) on deck directly above the galley. It will be a sort of integrated stove vent propane box combination. This will place the propane as close as possible to the stove. I will also build rubber seals into the box lid and a drain out the bottom dumping overboard via a thru hull to vent any stray gas fumes out and away. This will be a great improvement on the current arrangement, which places the tanks on deck all the way up forward. Besides the cost of running a 30' propane line, every time I activate the solenoid valve it takes 30 seconds or more before the gas actually reaches the stove. That's also a lot of line for propane to sit in and leak out of should a valve on the range ever stick.